Tin plate, as a material widely used in packaging fields such as food, beverages, chemicals and daily necessities, is favored for its superior anti-corrosion performance and mechanical strength. However, for ordinary consumers, the material and characteristics of tin plate may not be very clear. This article will explore the material composition, production process, advantages and application of tinplate plate in various industries in depth, revealing the secrets behind this important material.

Definition and composition of tin plate

Tin plate, in essence, is a tin-plated thin steel plate. As the name suggests, the core component of tin plate is steel, but its surface is tin-plated. The main purpose of tin plating is to prevent the steel plate from rusting in a humid environment, thereby extending its service life.

Specifically, tin plate consists of the following main parts:

1. Steel substrate: The basic material of tinplate plate is low-carbon steel, which has good mechanical strength and machinability.

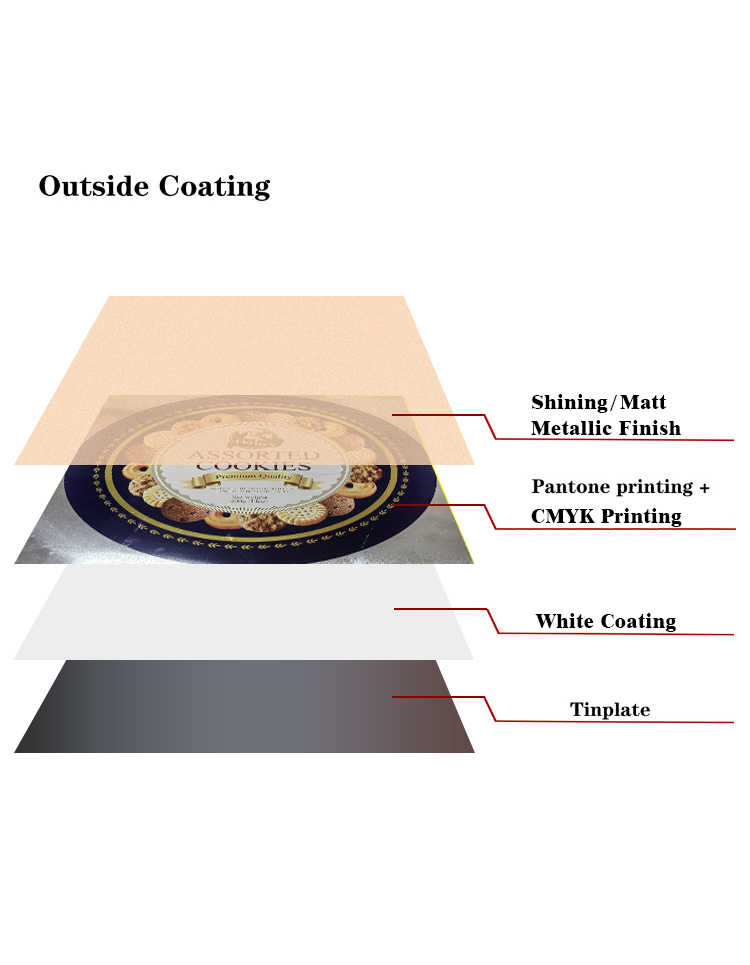

2. Tin plating: Both sides of the steel substrate are plated with a thin layer of tin, which plays a role in corrosion prevention and protection, and also makes the surface of tinplate plate smoother and more beautiful.

3. Passivation film: A passivation film can be added to the tin-plated layer. This film is usually obtained through chemical treatment, which can further improve the corrosion resistance of tin plate.

Production process of tin plate

The production process of tin plate mainly includes several key steps: cold rolling, annealing, tin plating, passivation and coating. Each step has an important impact on the quality of the final product.

1. Cold rolling: After pickling, the hot-rolled steel coil is cold-rolled to reduce its thickness and increase its surface finish.

2. Annealing: The cold-rolled steel plate is annealed to eliminate processing stress and improve its mechanical properties.

3. Tin plating: The annealed steel plate is electroplated in a tin plating machine to evenly plate tin on the surface of the steel plate. The thickness of the tin plating layer can be adjusted as needed.

4. Passivation: The tin-plated steel plate is passivated by a chemical solution to further enhance its corrosion resistance.

5. Coating: In some special applications, the surface of tin plate is also coated with a protective coating, such as paint or resin, to improve its durability and decorative effect.

Advantages of tin plate

The reason why tin plate is widely used is mainly due to its many advantages:

1. Excellent anti-corrosion performance: The tinning layer and passivation film effectively prevent the oxidation and corrosion of the steel substrate, which is particularly suitable for the packaging of food and beverages.

2. Good mechanical strength: The steel substrate provides good strength, making the tin plate less likely to deform and break during processing and use.

3. Excellent machinability: Tinplate plate has good plasticity and weldability, and can be easily processed into various shapes and sizes to meet different packaging needs.

4. Beautiful surface effect: The tinning layer and coating layer make the surface of tin plate smooth and shiny, and various exquisite patterns can be printed to enhance the appearance and market appeal of the product.

Application of tin plate in various industries

Due to its excellent performance, tin plate has been widely used in many industries:

1. Food industry: Tin plate is widely used in the packaging of canned foods, such as canned fruits, canned meats and canned vegetables. Its excellent anti-corrosion properties can ensure that food can be stored for a long time without deterioration under sealed conditions.

2. Beverage industry: tinplate plate is used to make beverage cans, such as beer, carbonated drinks and juice cans. It can not only effectively prevent the contact between beverages and the outside world, but also maintain the taste and freshness of beverages.

3. Chemical industry: tinplate plate is used to contain corrosive liquids such as paints, coatings and chemical solvents, and can provide good anti-corrosion protection.

4. Daily necessities industry: tinplate plate is used to make various daily necessities packaging, such as candy boxes, biscuit cans and tea cans. These products are not only moisture-proof and anti-corrosion, but also beautiful and generous, which enhances the added value of the products.

Future development trend

With the continuous advancement of science and technology and changes in market demand, tin plate materials are also constantly developing and innovating. In the future, the production process of tin plate will be more efficient and environmentally friendly, and new coating materials and technologies will further enhance its anti-corrosion performance and aesthetic effects.