In recent years, with the continuous expansion of the consumer goods market and the increasing demand for product packaging, tin plate printing, as an important packaging form, has been favored by more and more companies.

However, how to improve the product quality of tinplate printing has become the focus of the industry. This article will delve into this issue and analyze the key factors for tinplate printing to improve product quality from many aspects such as technology, process, and management.

Technological innovation helps improve quality

First of all, technological innovation is the core driving force to improve the quality of tin plate printing. In recent years, with the development of digital printing technology, the traditional tinplate printing process has been significantly improved. Digital printing not only improves printing accuracy, but also greatly shortens the production cycle. Compared with traditional offset printing and gravure printing, digital printing can achieve higher image resolution and color reproduction, making the quality of printed matter more detailed and realistic.

For example, some leading printing tinplate companies have introduced digital inkjet printing technology, which can achieve high-precision pattern printing on the tinplate surface and can be personalized to meet the needs of different customers. In addition, the application of UV printing technology has also greatly improved the wear resistance and gloss of printed matter, making tinplate packaging not only beautiful and elegant, but also durable.

Material selection and process optimization

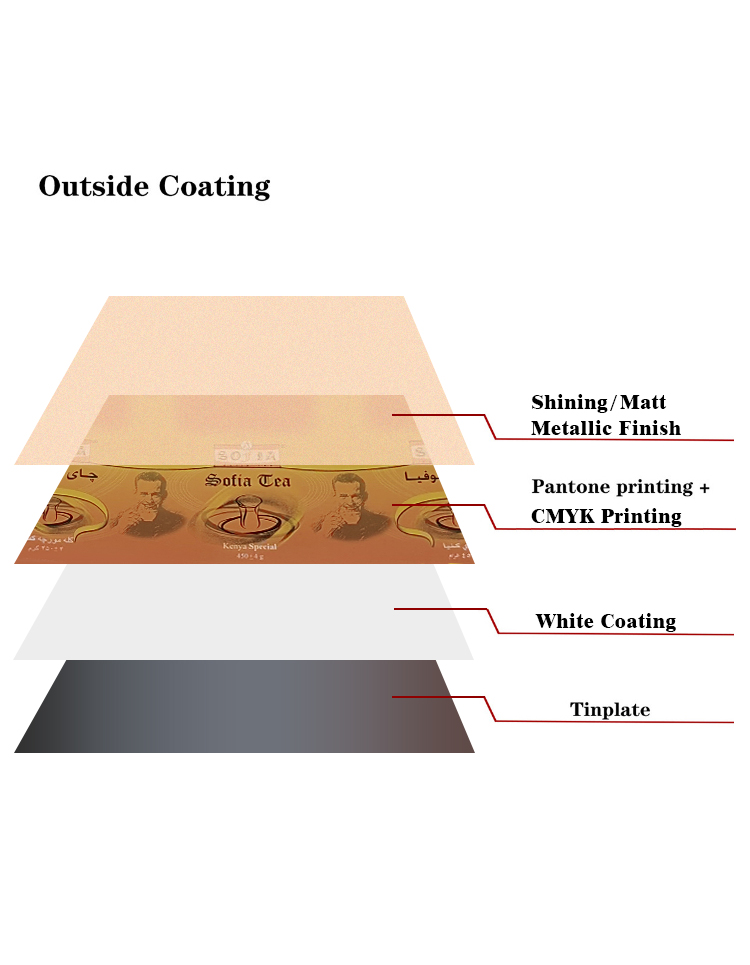

Secondly, material selection and process optimization are also important factors affecting the quality of tinplate printing. In terms of materials, high-quality tinplate raw materials are the basis for ensuring printing quality. Tinplate is a tin-plated thin steel plate with good anti-corrosion properties and mechanical strength. Therefore, choosing high-quality tinplate materials can effectively improve the durability and aesthetics of printed matter.

In terms of technology, refined production processes and strict quality control are key. Modern tinplate printing companies have achieved integrated production from raw materials to finished products by introducing advanced production equipment and automated production lines. During the printing process, parameters such as temperature, humidity and pressure are precisely controlled to ensure the color consistency and pattern clarity of the printed matter. In addition, through continuous optimization of the printing process, such as improving the ink formula and coating process, the printing quality can also be significantly improved.

Quality management and testing

Furthermore, a complete quality management system and testing methods are important guarantees for ensuring the quality of printing tinplate products. Modern enterprises generally adopt the ISO9001 quality management system and strictly monitor and manage all aspects of production by establishing scientific quality management processes. Quality management is not only the control of the production process, but more importantly, the inspection of raw materials, the maintenance of production equipment and the training of operators.

In order to ensure the stable quality of each batch of products, the company has introduced advanced testing equipment during the production process, such as colorimeter, gloss meter and abrasion resistance tester, to conduct comprehensive testing of the color, gloss and durability of the printed matter. In addition, through real-time monitoring and analysis of production data, quality problems in production can be discovered and solved in a timely manner to prevent substandard products from flowing into the market.

Environmental protection and sustainable development

While improving quality, environmental protection and sustainable development are also important issues in the tin plate printing industry. With the enhancement of environmental awareness and the introduction of relevant regulations, enterprises must consider environmental protection and resource conservation issues in the production process. For example, the use of environmentally friendly inks and degradable coatings can reduce environmental pollution; by optimizing production processes, energy consumption and waste emissions can be reduced to achieve green production.

Many tinplate printing companies actively promote environmental protection and sustainable development while improving product quality. For example, some companies have introduced recycling systems to recycle waste materials generated during the production process and reuse them in the production process, thereby reducing resource waste and environmental pollution. This not only helps enterprises improve their economic efficiency, but also enhances their social responsibility and market competitiveness.

Customer needs and market feedback

Finally, understanding customer needs and market feedback is an important means to improve the quality of printing tinplate. Companies should communicate with customers through multiple channels to understand their specific requirements and feedback on product quality. Through customer surveys, market research, etc., we understand market dynamics and consumer preferences, and continuously improve and optimize product quality.

Some companies (such as Chumboon Metal Packaging Corporation) establish customer feedback mechanisms to promptly collect and analyze customer experience and suggestions, and adjust product design and production processes according to market demand to ensure that products can meet the needs of the market and customers. At the same time, by participating in industry exhibitions and technical exchange activities, we learn about the latest industry dynamics and technology trends, and continuously improve our technical level and product quality.