Tinplate sheet, also known as tin-plated thin steel sheet, is widely used in food, beverage, chemical and other industries due to its excellent physical and chemical properties. One of its key characteristics is that it can withstand a certain amount of pressure, which makes it possible to use tinplate sheet under high pressure conditions.

So, how much pressure can tinplate sheet withstand? This article will comprehensively analyze the pressure-bearing performance of tinplate sheet from the aspects of material structure, pressure testing, and practical application of tinplate sheet.

Material structure and characteristics of tinplate sheet

1. Basic structure

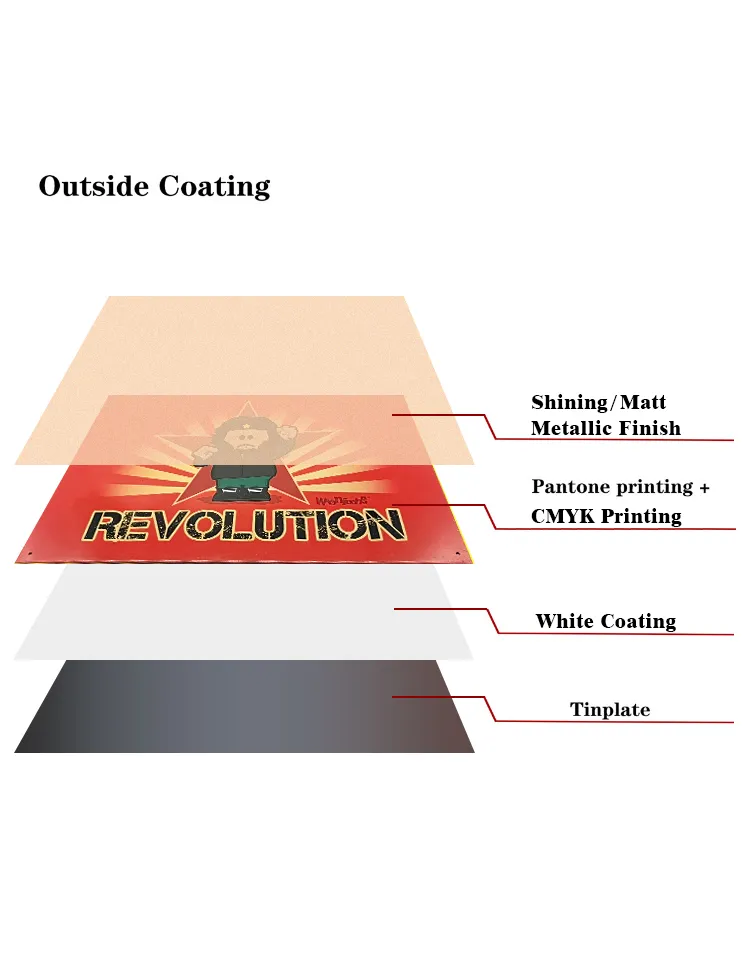

Tinplate sheet is a composite material made by plating a layer of tin on the surface of a thin steel plate. This structure not only gives the steel plate a higher strength, but also makes it have good anti-corrosion properties. Specifically, the structure of tinplate sheet includes:

● Steel base: usually low carbon steel or other alloy steel is used to provide the basic strength and toughness of the material.

● Tin layer: formed on the surface of the steel base through electroplating or hot-dip plating process, which plays an anti-corrosion role and enhances the appearance quality of the material.

2. Physical properties

The physical properties of tinplate sheet mainly include its density, hardness, tensile strength and yield strength. These properties directly affect its pressure bearing capacity:

● Density: about 7.85g/cm³, similar to steel.

● Hardness: usually between HR30T 50-80, depending on the composition and processing technology of the steel base.

● Tensile strength: usually between 300-500 MPa.

● Yield strength: generally 150-350 MPa.

How much pressure can tinplate sheet withstand?

In order to determine the pressure bearing capacity of tinplate sheet, a series of standardized tests are usually required. These tests include compressive strength test, yield strength test and fatigue test.

1. Compressive strength test

The compressive strength test mainly measures the maximum pressure that the material can withstand in the vertical direction. The test method is as follows:

● Sample preparation: Cut tinplate sheet samples of standard size.

● Test process: Gradually apply vertical pressure on the press until the sample is significantly deformed or broken.

● Data recording: record the maximum pressure value when the sample breaks.

Test results show that the compressive strength of tinplate sheet is usually between 200-400 MPa, depending on the composition and thickness of the steel base.

2. Yield strength test

The yield strength test measures the maximum pressure that a material can withstand before it undergoes permanent deformation under pressure. The test method is as follows:

● Sample preparation: Prepare tinplate sheet samples of standard size.

● Test process: Gradually apply pressure on the press while measuring the deformation of the sample.

● Data recording: Record the pressure value when the sample begins to undergo permanent deformation.

Test results show that the yield strength of tinplate sheet is usually between 150-350 MPa.

3. Fatigue test

The fatigue test evaluates the durability of the material under cyclic stress conditions. The test method is as follows:

● Sample preparation: Prepare tinplate sheet samples of standard size.

● Test process: Apply repeated pressure cycles to the sample on a fatigue testing machine until the sample breaks.

● Data recording: Record the number of cycles and the maximum pressure when the sample breaks.

Test results show that tinplate sheets can withstand thousands to tens of thousands of cycles when subjected to lower cyclic stresses (such as 50-150 MPa).

Pressure bearing performance in practical applications

Tinplate sheets are widely used in food cans, beverage cans, chemical containers and other fields, and their pressure bearing performance in practical applications is a key consideration.

1. Food cans

During the production process of food cans, tinplate sheets need to withstand a certain internal pressure to ensure that the cans do not deform or break during high-temperature sterilization. Normally, the internal pressure of food cans can reach 100-150 kPa, and the pressure resistance of tinplate sheets is sufficient to meet this requirement.

Case analysis:

A certain brand of metal cans uses tinplate sheets with a thickness of 0.24mm. Through compressive strength testing, its maximum pressure bearing capacity is 350 kPa, which is much higher than the internal pressure that cans need to withstand during production, ensuring the safety and stability of the cans.

2. Beverage cans

Beverage cans, especially carbonated beverage cans, need to withstand high internal air pressure. Normally, the internal pressure of a carbonated beverage can is about 300-500 kPa, while the pressure resistance of tinplate sheet can reach or even exceed this range.

Case analysis:

The carbonated beverage cans of a well-known beverage brand use tinplate sheet with a thickness of 0.28mm. Through the pressure test, its maximum pressure bearing capacity is 450 kPa, which is enough to ensure that there is no deformation or leakage during transportation and storage.

3. Chemical containers

Containers used to store and transport chemicals need to have higher pressure resistance and corrosion resistance. Tinplate sheet has become one of the ideal materials for chemical containers due to its excellent corrosion resistance and high compressive strength.

Case analysis:

A chemical company uses a chemical container made of tinplate sheet with a thickness of 0.30mm. Through strict pressure testing, its maximum pressure bearing capacity is 400 kPa, and after anti-corrosion treatment, it can store corrosive chemicals for a long time without leakage.

What are the factors that affect the pressure bearing capacity of tinplate sheet?

The pressure bearing capacity of tinplate sheet is affected by many factors, including material thickness, manufacturing process, coating quality, etc.

1. Material thickness

The thickness of tinplate sheet is one of the key factors affecting its pressure bearing capacity. Generally speaking, the greater the thickness, the higher the compressive strength and yield strength of the material.

Example analysis:

Under the same manufacturing process conditions, the compressive strength of 0.24mm thick tinplate sheet is 350 MPa, while the compressive strength of 0.30mm thick tinplate sheet can reach 400 MPa.

2. Manufacturing process

The manufacturing process has an important influence on the physical properties of tinplate sheet. Advanced manufacturing processes can improve the uniformity and strength of the material, thereby enhancing its pressure bearing capacity.

Example analysis:

The internal structure of tinplate sheet made by cold rolling process is more uniform, and the compressive strength and yield strength are significantly higher than those of tinplate sheet made by hot rolling process.

3. Coating quality

The uniformity and thickness of the tin layer directly affect the anti-corrosion performance and pressure bearing capacity of tinplate sheet. High-quality coating can effectively protect the steel base and prevent corrosion and cracking under high pressure conditions.

Case analysis:

A brand of tinplate sheet made by electroplating tinning process has uniform tin layer thickness, compressive strength of 400 MPa, and anti-corrosion performance is significantly better than traditional hot-dip tinning process.

Conclusion

Through a comprehensive analysis of the material structure, pressure test, practical application and influencing factors of tinplate sheet, the following conclusions can be drawn:

1. Tinplate sheet has strong pressure bearing capacity: its compressive strength is usually between 200-400 MPa, and its yield strength is between 150-350 MPa, which can meet the needs of most food, beverage and chemical containers.

2. Diverse influencing factors: factors such as material thickness, manufacturing process and coating quality will affect the pressure bearing capacity of tinplate sheet. In practical applications, it is necessary to select appropriate tinplate sheet specifications and production processes according to specific needs to ensure its safety and stability.

3. Broad application prospects: tinplate sheet has become an ideal material for various high-pressure containers due to its excellent pressure bearing performance and anti-corrosion properties, and has been widely used in the food, beverage and chemical industries.

Through the detailed analysis of this article, we hope to help industry practitioners and consumers better understand the pressure-bearing performance of tinplate sheet and its performance in practical applications, and ensure that its advantages are safely and reliably exerted during production and use.