Tinplate, as an important packaging material, is widely used in food, beverage, chemical and other industries due to its excellent physical and chemical properties. With the diversification and personalization of market demand, more and more companies and consumers are beginning to pay attention to the customized services of tinplate products.

So, can tinplate products be customized? How to customize? This article will analyze the customized services of tinplate products in detail from the aspects of customization needs, customization process, actual cases and precautions of tinplate products.

What is the customization demand for tinplate products?

1. Diversification of market demand

With the continuous changes in the consumer market, the demand of enterprises and consumers for packaging materials is becoming more and more diversified. Industries such as food, beverages and chemical products have put forward higher requirements on the shape, size, printing pattern and function of packaging materials. As a high-performance packaging material, tinplate's plasticity and processability make it an ideal choice for customized services.

2. The demand for brand personalization

Brand personalization is one of the important means of modern marketing. Through customized packaging, enterprises can better display their brand image and enhance their market competitiveness. The customized service of tinplate products can meet the personalized needs of enterprises in shape design, pattern printing and functionality, thereby enhancing brand value.

Can tinplate products be customized? How to customize?

The customization of tinplate products is a complex process involving multiple links. The following is a typical customization process:

1. Demand analysis

The first step in the customization process is demand analysis. Enterprises need to clarify their specific needs for tinplate products, including shape, size, printing pattern, function and other requirements.

Steps:

● Communication: The enterprise communicates with the supplier in detail to clarify the customization requirements.

● Demand document: The requirements are organized into documents for subsequent design and production reference.

2. Design and development

After clarifying the requirements, enter the design and development stage. Designers carry out product appearance design and functional design according to the needs of the enterprise.

Steps:

● Appearance design: According to the demand document, design the shape, size and appearance pattern of the product.

● Functional design: Design the functionality of the product, such as special requirements such as moisture-proof and anti-corrosion.

● Design review: Conduct a design review with the enterprise to ensure that the design plan meets the requirements.

3. Material selection and preparation

After the design is determined, the material selection and preparation stage begins. The supplier selects suitable tinplate materials according to the design plan and performs preliminary processing.

Steps:

● Material selection: Select tinplate materials of appropriate specifications according to design requirements.

● Material preparation: Perform preliminary processing of the materials, such as cutting, deburring, etc.

4. Mold making

Mold making is a key link in the customization of tinplate products. According to the design plan, make the corresponding mold for subsequent molding processing.

Steps:

● Mold design: Design the mold according to the product design plan.

● Mold making: Make the mold according to the design drawings, and test and adjust it.

5. Molding processing

After the mold is made, the molding processing stage begins. The tinplate material is processed into the required shape and size through stamping, stretching, bending and other processes.

Steps:

● Stamping molding: The tinplate material is processed into a preliminary shape through the stamping process.

● Stretching processing: Secondary molding is performed through the stretching process as needed.

● Bending: bend and edge the product to ensure accurate size and beautiful appearance.

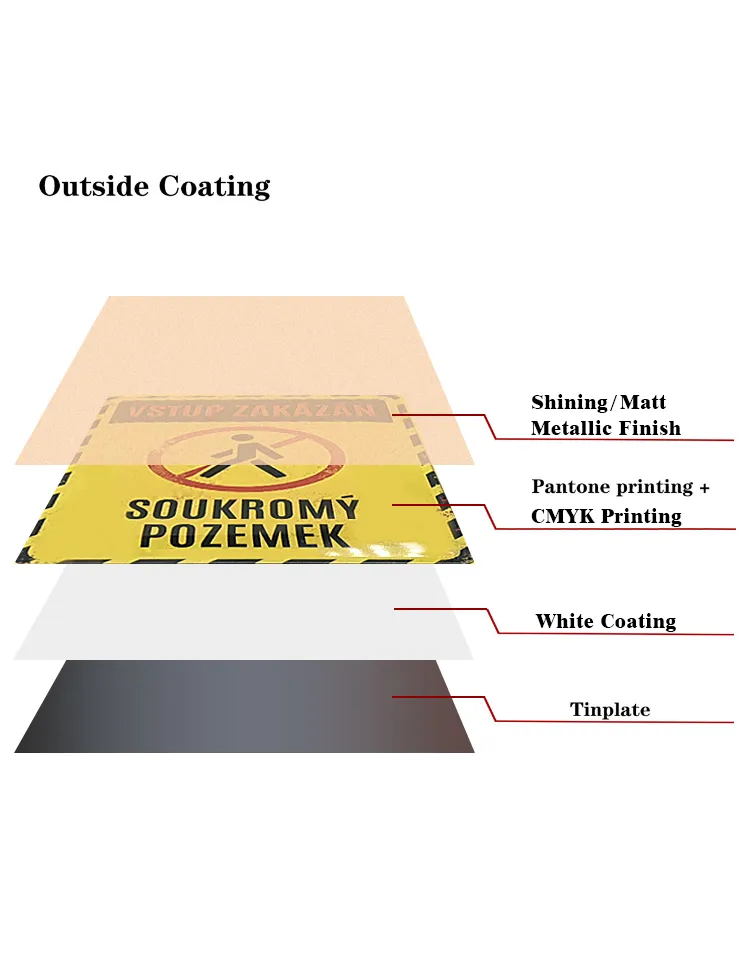

6. Surface treatment and printing

After the molding process is completed, enter the surface treatment and printing stage. According to the design plan, the product is surface treated and pattern printed.

Steps:

● Surface treatment: polishing, spraying and other surface treatments are performed to improve the beauty and durability of the product.

● Pattern printing: according to the design plan, pattern printing is performed to ensure that the pattern is clear and beautiful.

7. Quality inspection

Quality inspection is an important link to ensure that customized products meet the requirements. Through strict quality inspection, ensure that the product meets the needs of the enterprise in terms of shape, size, printing pattern and functionality.

Steps:

● Appearance inspection: Check whether the appearance of the product meets the design requirements.

● Dimension inspection: measure whether the size of the product meets the design standards.

● Functional test: perform functional test to ensure that the performance of the product meets the requirements.

8. Packaging and delivery

After passing the quality inspection, enter the packaging and delivery stage. According to the requirements of the enterprise, the product is packaged and delivered to the customer on time.

Steps:

● Product packaging: Packaging according to requirements to ensure that the product is not damaged during transportation.

● Delivery logistics: Arrange logistics transportation to deliver the product to customers on time.

Actual cases of customized tinplate products

1. Case of customized food packaging

In order to enhance its brand image, a well-known food brand decided to customize a batch of high-end food packaging. Through cooperation with suppliers, detailed demand analysis and design, a tinplate food can with unique shape and exquisite pattern was finally completed.

Customization process:

● Demand analysis: Clarify brand image and packaging function requirements.

● Design and development: Design unique shapes and patterns, and conduct reviews.

● Material selection: Purchase high-quality tinplate materials for preliminary processing.

● Mold making: Make molds according to the design plan, and test and adjust them.

● Molding processing: Complete molding processing through stamping, stretching and bending processes.

● Surface treatment and printing: Polishing, spraying and pattern printing are carried out to ensure beauty and durability.

● Quality inspection: Strict quality inspection is carried out to ensure that the product meets the requirements.

● Packaging and delivery: arrange packaging and logistics, and deliver to customers on time.

2. Customized chemical container case

In order to meet the storage needs of special chemicals, a chemical company decided to customize a batch of highly corrosion-resistant tinplate chemical containers. Through cooperation with suppliers, demand analysis and design, a high-performance tinplate chemical container was finally completed.

Customization process:

● Demand analysis: clarify the storage requirements of chemicals and the functional requirements of containers.

● Design and development: design shapes and functions that meet the requirements, and conduct reviews.

● Material selection: purchase highly corrosion-resistant tinplate materials for preliminary processing.

● Mold making: make molds according to the design plan, and test and adjust them.

● Molding: complete molding through stamping, stretching and bending processes.

● Surface treatment and printing: anti-corrosion treatment and pattern printing to ensure durability and aesthetics.

● Quality inspection: conduct strict quality inspection to ensure that the product meets the requirements.

● Packaging and delivery: arrange packaging and logistics, and deliver to customers on time.

Conclusion

Through a comprehensive analysis of the customization needs, customization process, actual cases and precautions of tinplate products, the following conclusions can be drawn:

1. Tinplate products can be customized: Enterprises and consumers can customize tinplate products that meet the requirements according to specific needs.

2. The customization process is complicated: The customization of tinplate products involves multiple links such as demand analysis, design and development, material selection, mold making, molding, surface treatment and printing, quality inspection, packaging and delivery.

3. Key precautions: During the customization process, enterprises need to clarify their needs, select suitable suppliers, conduct strict quality control, and reasonably arrange delivery time to ensure the quality and delivery time of customized products.

Through the detailed analysis of this article, it is hoped that it can help enterprises and consumers better understand the customized services of tinplate products and ensure that their advantages are safely and reliably exerted during production and use.