Empty Aerosol Tin Can For Air Freshener 300ml

1.QC: We perform 100% leaking testing for each cans, 2. Popularity: 250ml Aerosol Tinplate Body Spray Can is hot sale to the world 3.Delivery time :15-20 days

1.QC: We perform 100% leaking testing for each cans, 2. Popularity: 250ml Aerosol Tinplate Body Spray Can is hot sale to the world 3.Delivery time :15-20 days

1.30 years aerosol tin can making experience ,do one thing and do it well . 2.All the equipment are from European ,such Germany KBA 4/6 Color printing machine ,Japan Fuji 4 color printing machine 3.Product are exported to morn than 40 countries ,such as USA ,Mexico ,Brazia ,Argentina ,India ,Malasia ,UAE ,South Africa. 4.Has passed certificate :ISO ,SGS,Sedex ,DOT ``

1.Payment term: Normally T/T payment, other payment terms is also available. 2.Quality assurance - European automatic aerosol can production line 3.History: over 30 years manufacturing and over 15 years export experience on Aerosol Empty Tin Can 4.Delivery: Aerosol Tinplate Can 15 days fast delivery

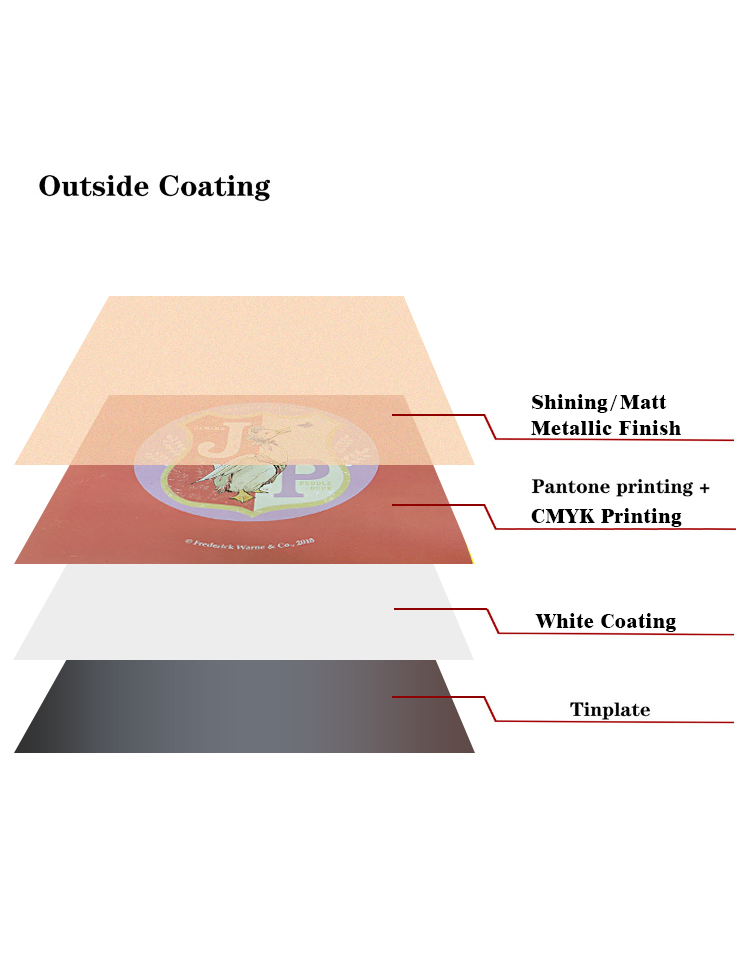

To manufacture high quality tin can, the choice of tinplate hardness T3/T4 plays a vital role in determining the strength and durability of the final product. Additionally, printing on tin cans enhances their aesthetics and brand recognition, making printing tin can ideal for a variety of applications, including fabulous tin cases for candy and other products.

Tinplate hardness is classified using the T rating system, with T2 being the softest and T5 being the hardest. T3 and T4 are commonly used grades for tinplate plates used in packaging applications. T3 has moderate hardness and is suitable for forming various shapes without affecting the integrity of tinplate. T4, on the other hand, is slightly harder, providing increased strength and resistance to deformation during handling and storage. The appropriate tinplate hardness can be selected based on the specific requirements of the packaging design and the type of product to be packaged.

The high quality tin can printing process involves using advanced printing technology to apply high quality graphics, designs, logos and text directly to the tinplate surface. CMYK color schemes are often used to achieve vibrant and accurate color reproduction, ensuring that the printed image on the tin is visually appealing and reflects the brand image. Cans can be printed on both the outside and inside, providing ample scope for creative and informative packaging designs. Customized candy tin cases can be made using high quality tinplate with required hardness (T3/T4) and printing capabilities to showcase vibrant and attractive designs.

| Item | SPCC Grade T57 2.8/2.8 Tinplate Sheet |

| Material Grade | SPCC, MR |

| Temper(BA&CA) | T1,T2,T3,T4,T5,DR8,DR9 |

| Tin Coating | 1.1~11.2g/m2 |

| Thickness | 0.15~0.70mm(Tolerance: +/- 0.01 mm) |

| Width | 10~600mm (Tolerance: 0~3mm) |

| Coil inside diameter | 420/508mm |

| Coil Weight | 1~3 MT |

| Surface Finish | Bright, Stone, Silver, Matte,Gold Lacquered |

| Application | Wide used in the field of metal package or can making like chemical can,aerosol can and different food can production |

FAQ

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:What are the shipping ports?

A:Under normal circumstances, we ship from Guangzhou ,Shenzhen port, or you can choose other ports according to your needs.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

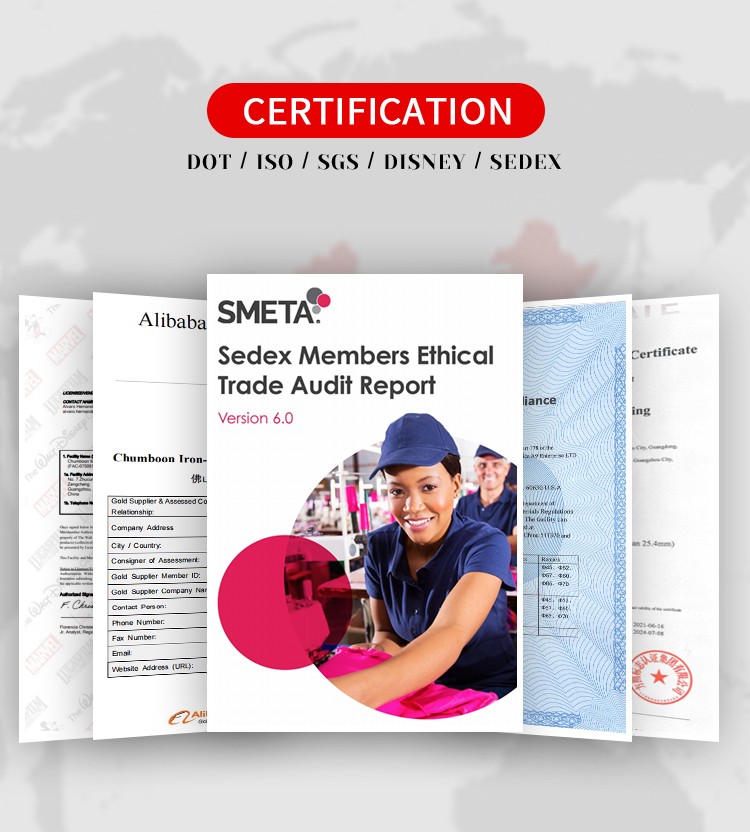

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, Disney and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 30-45 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation.

Q: How can I pay you?

A: For mass production goods, you need to pay 30% deposit before production and 70% balance upon shipment. The most common way to pay us is by T/T. LC,DP,DA is also acceptable.