In recent years, tin plate has attracted much attention due to its excellent anti-corrosion performance and wide application fields. However, many people still have doubts about whether tin plate will rust.

This article will explore the composition, characteristics and anti-rust mechanism of tin plate in depth, and analyze how to prevent and deal with the rust problem of tin plate in practical applications.

What is tin plate?

Tin plate is a thin steel plate with a tin-plated surface. The main component is iron, and a thin layer of tin is plated on its surface. This layer of tin not only gives tin plate good anti-corrosion properties, but also makes it have a beautiful appearance and good processing performance. Therefore, tin plate is widely used in food cans, beverage cans, cosmetic packaging, chemical product containers and other fields.

Anti-rust principle of tin plate

The anti-rust ability of tin plate mainly depends on its surface tin layer. This layer of tin can not only isolate air and moisture from contact with the iron substrate, prevent the occurrence of oxidation reaction, but also protect the iron substrate through its own oxidation in some cases.

1. Physical barrier: The tin layer acts as a physical barrier, which effectively isolates the iron substrate from oxygen and moisture in the outside world, prevents the iron substrate from oxidation reaction, and thus avoids rust.

2. Chemical protection: Tin forms a layer of tin oxide (SnO2) in the air. This oxide film has good stability and can further enhance the anti-corrosion ability.

3. Electrochemical protection: When the tin plating layer is damaged, tin and iron form galvanic corrosion. Since the electrode potential of tin is higher than that of iron, tin will be oxidized first, thus protecting the iron substrate.

Will tin plate rust?

Although tin plate has excellent anti-rust properties, tin plate may still rust in some cases. Here are some common situations:

1. Damage to the tin plating layer: If the tin plating layer of the tin plate is mechanically damaged, such as scratches, collisions, etc., the exposed iron substrate will come into contact with air and moisture, resulting in oxidation reactions and rusting.

2. Chemical corrosion: In acidic or alkaline environments, both the tin plating layer and the iron substrate may undergo chemical reactions, resulting in a decrease in the protective effect, thus causing rust problems.

3. Long-term exposure: In a humid environment, tin plates that are exposed for a long time may gradually oxidize due to the tiny pores in the tin layer, especially in the presence of electrolytes (such as salt), which makes electrochemical corrosion more likely.

Methods to prevent tin plates from rusting

In order to better utilize the anti-rust properties of tin plates, the following are some common anti-rust measures:

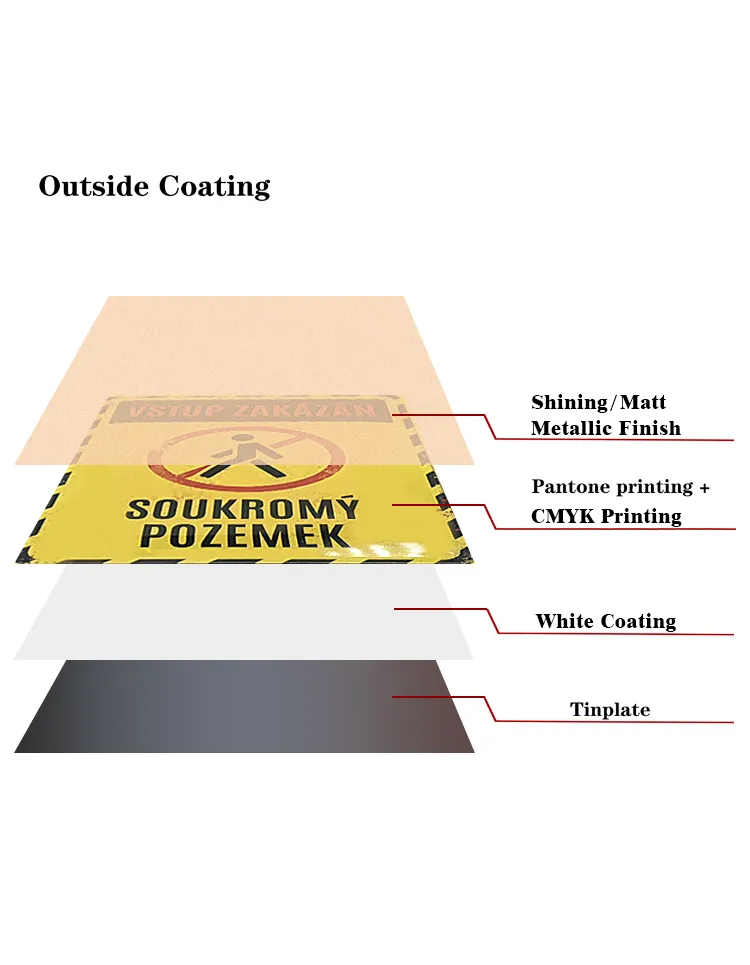

1. Improve the quality of the tin layer: By improving the tinning process and increasing the thickness and uniformity of the tin layer, the anti-rust properties of tin plates can be significantly improved.

2. Coating a protective layer: Coating a layer of organic coating or other protective layer on the surface of tin plates can further enhance their anti-corrosion properties. Common coatings include epoxy resin, polyester, etc.

3. Avoid mechanical damage: During production and transportation, mechanical damage to the surface of tin plates should be avoided as much as possible to protect the integrity of the tin layer.

4. Control the storage environment: When storing tin plate products, they should be kept dry and ventilated to avoid long-term storage in a humid or acid-base environment.

Application of tin plates in various fields

Tin plates are widely used in various fields due to their excellent anti-corrosion properties and machinability. The following are some typical application scenarios and their anti-rust requirements:

1. Food and beverage packaging: Food cans and beverage cans made of tin plate are widely used in the food industry. Due to direct contact with food, tin plate needs to have excellent anti-rust properties to ensure food safety. Usually, a non-toxic organic coating is coated on the inner wall of food cans to enhance the anti-corrosion performance.

2. Cosmetic packaging: tin plate is also widely used in cosmetic packaging, such as perfume bottle caps, cosmetic boxes, etc. In order to prevent the ingredients in cosmetics from corroding the tin plate, a protective coating is usually applied to its surface.

3. Chemical product containers: tin plate is used for containers of chemical products, such as paint cans, lubricating oil barrels, etc., which need to have high anti-corrosion properties to prevent chemicals from corroding the containers. Usually, such containers are also coated with a chemical corrosion-resistant coating on the inner wall.

4. Industrial parts: tin plate is also widely used in some industrial parts, such as battery shells, electronic component shells, etc. These parts have high requirements for anti-rust performance, and usually use high-quality tin plating and coating technology to ensure their long-term performance.

Conclusion

As a high-quality anti-rust material, tin plate has a wide range of application prospects. However, in order to give full play to its anti-rust performance, enterprises and consumers need to understand its characteristics and usage requirements, take corresponding protective measures, and ensure the long-term and stable use of tin plate products.