Tin can is widely used in various fields such as food, cosmetics, gifts, etc., and is favored for its anti-corrosion and rust-free properties. Many people have used or seen tin cans in daily life, but few people have a deep understanding of why tin cans do not rust. This article will explore this issue in detail through scientific principles, material properties and application examples.

Basic structure and materials of tin can

1. Composition of tin can

The main material of tin can is tinplate, which is composed of low-carbon steel and tin. Low-carbon steel provides the necessary strength and toughness, while tin gives anti-corrosion properties. Tinplate is coated with a layer of tin on the surface of the steel plate through electroplating or hot-dip coating, giving it the dual advantages of tin and steel.

2. Characteristics of tin

Tin is a chemical element with the symbol Sn and atomic number 50. The chemical properties of tin are relatively stable and it is not easy to react with oxygen in the air to form a protective oxide film, thereby preventing further oxidation and corrosion. Tin has a low melting point, but has good stability at room temperature.

The principle of rusting

1. The rusting process of iron and steel

Rust refers to the process in which iron or steel reacts chemically with oxygen and water in a humid environment to form iron oxide (rust). The chemical equation for rust is as follows: 4Fe+3O2+6H2O→4Fe(OH)3

The iron hydroxide generated by this reaction is further dehydrated to form rust (Fe2O3·nH2O). Rust is porous and cannot effectively prevent the continued erosion of air and water, resulting in increased corrosion of iron or steel.

2. The anti-corrosion principle of tin

Unlike iron and steel, tin will not rust in the air. This is because tin can form a dense protective film of tin oxide (SnO2) on the surface. This oxide film has good stability and corrosion resistance, and can effectively prevent air and moisture from further corroding the tin material. This is also an important reason why tin can remain rust-free for a long time.

Anti-rust mechanism of tin-plated steel sheet

1. Electroplating process

Electroplating is one of the most commonly used processes for tin-plated steel sheet. Through the electrolytic process, a thin layer of tin is evenly coated on the surface of the steel plate. The electroplated tin layer not only gives the steel plate excellent anti-corrosion properties, but also maintains the strength and toughness of the steel. The thickness of this tinned layer is usually between 1 and 10 microns, which is enough to effectively prevent the steel plate from rusting.

2. Hot-dip tinning process

Hot-dip tinning is another common tinning process. The steel plate is immersed in molten tin liquid to form a layer of tin coating on its surface. The hot-dip tinning layer is usually thicker and has stronger anti-corrosion properties. The hot-dip tinning process is particularly suitable for environments that require high corrosion resistance, such as the production of food cans and cosmetic cans.

Application of tin can in various industries

1. Food industry

Food cans are one of the most widely used areas for tin cans. Tin can can effectively prevent food from contacting with air and extend the shelf life of food. The tinned layer on the surface of tin can not only prevents rust, but also resists the corrosion of acidic foods, ensuring the safety and hygiene of food.

2. Cosmetics industry

Cosmetics have extremely strict requirements on packaging materials, and need to ensure the purity and stability of the product. Tin can is an ideal choice for cosmetic packaging due to its rust-proof and corrosion-resistant properties. For example, many high-end creams and balms are packaged in tin cans to ensure product quality.

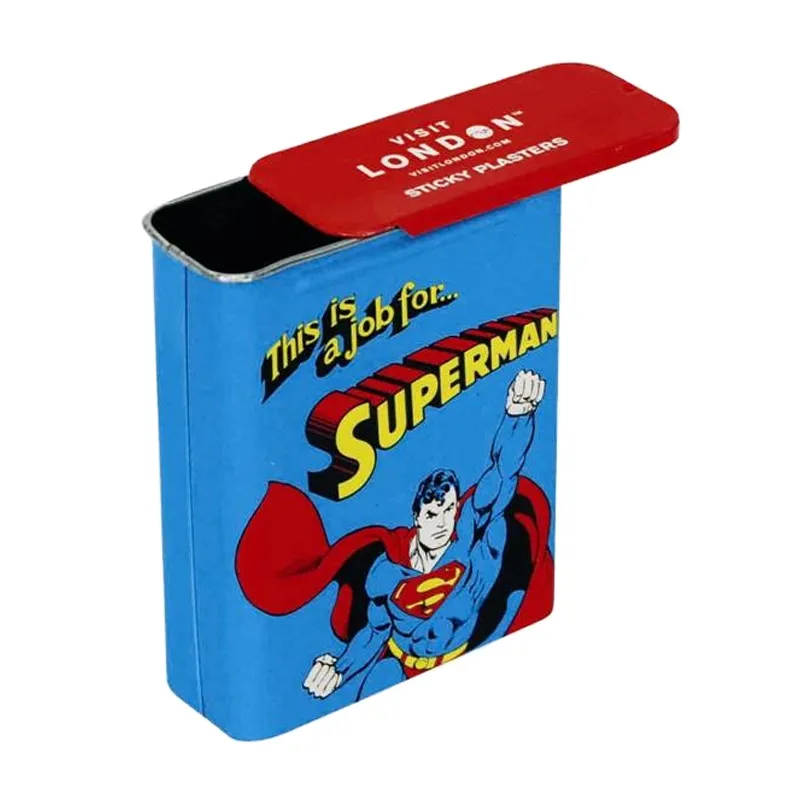

3. Gift and craft industry

Tin can is also widely used in the packaging of gifts and crafts. Its rust-proof, moisture-proof and beautiful features make tin can the preferred material for gift packaging. For example, many high-end tea, coffee and candy gift boxes are packaged in tin cans, which not only improves the grade of the product but also extends its shelf life.

Other advantages of tin can rust-proof

1. Environmental protection and recyclability

Tin can is an environmentally friendly packaging material. Both tin and steel are recyclable resources. Tin can can be recycled through recycling processes after its service life, reducing resource waste and environmental pollution. In contrast, the recycling rate of plastic packaging is low and has a greater impact on the environment.

2. Safety and hygiene

The application of tin can in food and drug packaging fully reflects its safety and hygiene. The tin coating can effectively prevent the penetration and dissolution of harmful substances, ensuring the purity and safety of the contents. In addition, tin cans do not produce harmful substances during processing and meet the safety standards for food and drug packaging.

3. Aesthetics and decorativeness

The surface of tin cans is smooth and easy to print and decorate. Through high-quality printing and coating processes, exquisite patterns and brand logos can be achieved on the surface of tin cans, enhancing the market competitiveness and brand image of the products. This makes tin cans popular in gifts, cosmetics and high-end food packaging.

Conclusion

The reason why tin cans do not rust is mainly due to the structure of its tin-plated thin steel plate and the anti-corrosion properties of tin. The tin coating forms a dense protective film on the surface of the steel plate, which can effectively prevent erosion by air and moisture, thereby maintaining the rust-proof properties of tin cans. The wide application of tin cans in the fields of food, cosmetics, gifts, etc. not only reflects its superior anti-corrosion properties, but also demonstrates its multiple advantages such as environmental protection, safety, and beauty.

In the future, with the continuous application of new materials and new processes and the promotion of environmentally friendly packaging, the market prospects of tin cans will be broader. Enterprises should seize this development opportunity and continuously innovate and improve product quality to meet market demand and consumer expectations.