As an important packaging container, candy tin box is not only used to store and protect candy, but also plays an important role in enhancing the aesthetics and brand value of products. Choosing the right material is crucial to the performance, cost and market competitiveness of candy tin box.

This article will explore the best material for making candy tin box, analyze the advantages and disadvantages of various materials, and give reasonable suggestions based on actual application cases.

Basic functional requirements of candy tin box

1. Protection function:

One of the main functions of candy tin box is to protect candy from the external environment, including moisture, oxygen, light and mechanical damage. The right material should have good barrier properties and strength to ensure the quality and taste of candy.

2. Aesthetics:

Candy tin box is usually used for gift packaging, so its appearance design and decorativeness are particularly important. The material should be easy to process, print and decorate to achieve exquisite packaging effects and enhance the market appeal of the product.

3. Safety:

As a food packaging material, the safety of candy tin box is crucial. The material should comply with the relevant standards of food contact materials, ensure that it is non-toxic and harmless, and does not affect the flavor and safety of the candy.

4. Sustainability:

With the increase of environmental awareness, the material selection of candy tin box also needs to consider environmental protection and sustainability. The material should have characteristics such as recyclability, degradability or low carbon emissions to reduce the impact on the environment.

What is the best material for making candy tin box?

1. Metal material

Metal materials mainly include tinplate and aluminum, which are widely used in the production of candy tin box.

a. Tinplate: Tinplate is a material with a thin layer of tin on the surface of low-carbon steel, which has good corrosion resistance and strength.

Advantages:

● Strong corrosion resistance: The tin layer can effectively prevent the steel from rusting and protect the internal candy.

● High strength: The steel has good mechanical properties and can withstand external pressure and collision.

● Easy to print and decorate: The surface of tinplate is smooth, suitable for high-quality printing and coating, and can achieve exquisite patterns and text.

Disadvantages:

● High cost: Compared with plastic and paper materials, the cost of tinned steel sheets is higher.

● Heavy weight: Metal materials are heavy and not suitable for portability and transportation.

b. Aluminum: Aluminum is a lightweight, corrosion-resistant metal material, widely used in the production of high-end candy tin boxes.

Advantages:

● Lightweight: Aluminum is lightweight and easy to carry and transport.

● Strong corrosion resistance: Aluminum has natural antioxidant properties and is not easy to rust.

● Good plasticity: Aluminum is easy to process and can achieve complex shape designs.

Disadvantages:

● High cost: The price of aluminum is relatively high, which increases the production cost.

● Easy to deform: Aluminum has a low hardness and is easy to deform when subjected to large external forces.

2. Plastic material

Plastic materials mainly include polyethylene (PE), polypropylene (PP) and polyethylene terephthalate (PET), etc., which are widely used in the production of candy tin boxes.

a. Polyethylene (PE): Polyethylene is a commonly used plastic packaging material with good chemical resistance and toughness.

Advantages:

● Low cost: Polyethylene material is cheap and suitable for large-scale production.

● Good toughness: Polyethylene has good toughness and can resist external impact.

● Strong chemical resistance: Polyethylene has good tolerance to chemicals such as acids and alkalis.

Disadvantages

● Poor heat resistance: Polyethylene has poor heat resistance and is not suitable for high temperature environments.

● High air permeability: Polyethylene's barrier properties are not as good as other materials, which may affect the shelf life of candies.

b. Polypropylene (PP): Polypropylene is a transparent, heat-resistant plastic material that is widely used in food packaging.

Advantages:

● Good heat resistance: Polypropylene has high heat resistance and is suitable for hot filling and high-temperature sterilization.

● High transparency: Polypropylene has good transparency and is easy to display candies.

● Recyclable: Polypropylene is easy to recycle and meets environmental protection requirements.

Disadvantages:

● Poor toughness: Polypropylene has slightly worse toughness than polyethylene and is prone to become brittle at low temperatures.

● Average printing effect: Polypropylene has a low surface smoothness and the printing effect is not as good as metal materials.

c. Polyethylene terephthalate (PET): PET is a transparent and tough plastic material widely used in beverage bottles and food packaging.

Advantages:

● High transparency: PET has excellent transparency and can clearly display candy.

● High strength: PET has high mechanical strength and is not easy to deform and break.

● Good chemical resistance: PET has good tolerance to a variety of chemicals.

Disadvantages:

● High cost: The price of PET is relatively high, which increases the production cost.

● General environmental protection: The recycling rate of PET is low and has a greater impact on the environment.

3. Paper materials

Paper materials mainly include kraft paper, white cardboard and corrugated paper, which are widely used in the production of environmentally friendly candy tin boxes.

a. Kraft paper: Kraft paper is a tough and durable paper material with good moisture resistance.

Advantages:

● Environmental protection: Kraft paper is degradable, recyclable and environmentally friendly.

● Low cost: Kraft paper is cheap and suitable for large-scale production.

● Good printing effect: The surface of kraft paper is easy to print, and can achieve exquisite patterns and text.

Disadvantages:

● General protective performance: The mechanical strength and barrier properties of kraft paper are not as good as metal and plastic materials.

● Poor durability: Kraft paper is susceptible to moisture and deformation, and is not suitable for long-term storage.

b. White cardboard: White cardboard is a high-quality paper material with good smoothness and printing effect.

Advantages:

● Beautiful: The surface of white cardboard is smooth, suitable for high-quality printing and decoration.

● Environmental protection: White cardboard is degradable and recyclable, meeting environmental protection requirements.

● Good processability: White cardboard is easy to cut and fold, and is convenient for design and production.

Disadvantages:

● Limited protective performance: The moisture-proof and protective properties of white cardboard are not as good as metal and plastic materials.

● General durability: White cardboard is easily affected by the external environment and is not suitable for long-term storage.

4. Composite materials

Composite materials refer to composite structures composed of two or more materials, combining the advantages of different materials, and are widely used in the production of high-performance candy tin boxes.

a. Metal-plastic composite materials: Metal-plastic composite materials combine the advantages of metal and plastic, and have good protective performance and aesthetics.

Advantages:

● Strong protective performance: The metal layer provides good mechanical strength and corrosion resistance, and the plastic layer provides excellent barrier properties.

● Moderate weight: The weight of the composite material is between metal and plastic, which is easy to carry and transport.

● Good processability: The composite material is easy to process and form, and is suitable for a variety of design requirements.

Disadvantages:

● High cost: The production cost of composite materials is high, which increases the price of the product.

● Poor environmental protection: The recycling of composite materials is difficult and has a greater impact on the environment.

Practical application case analysis

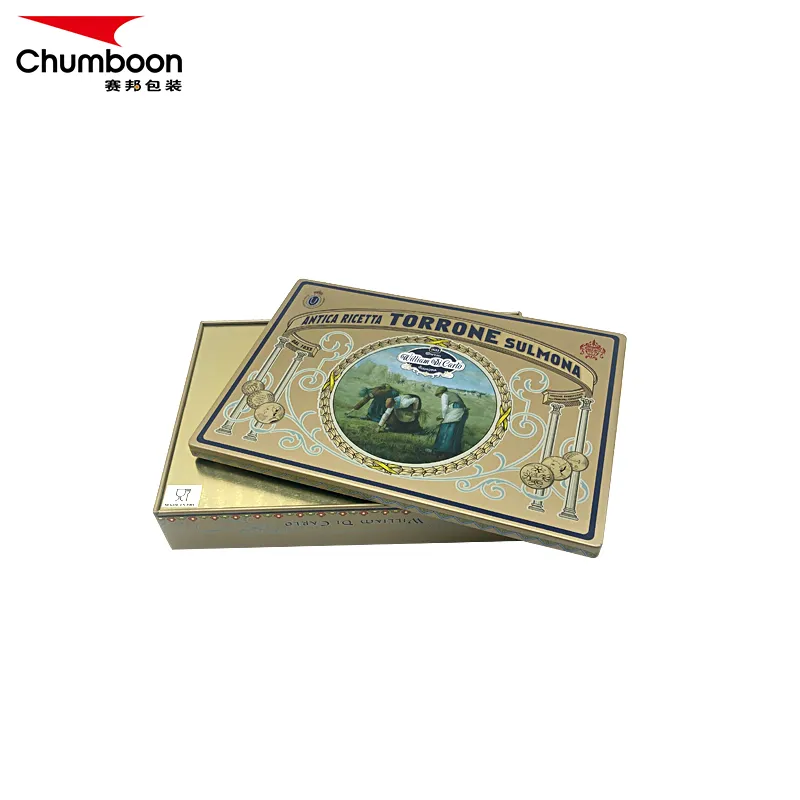

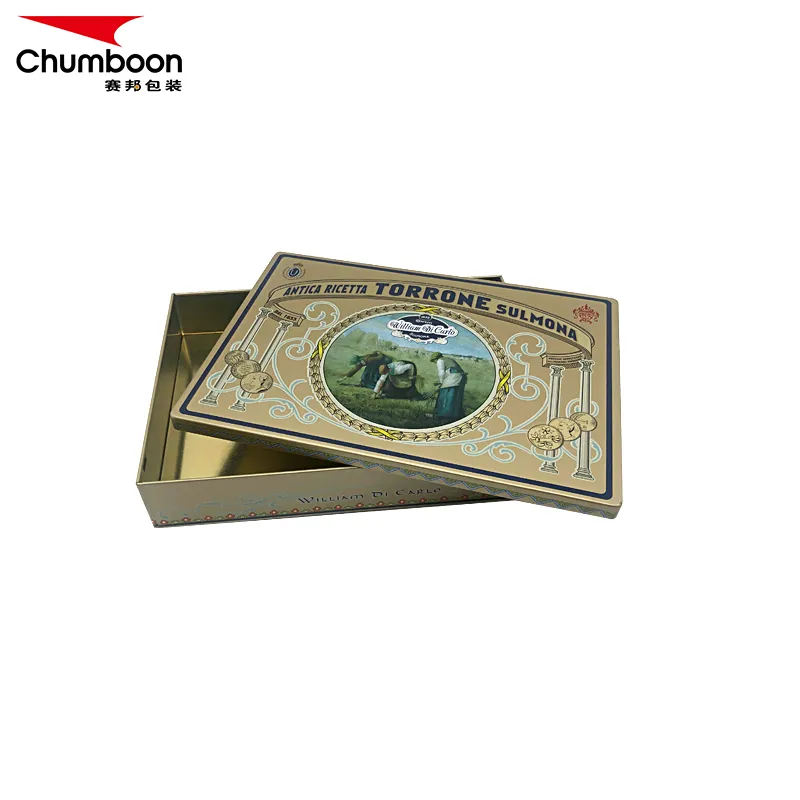

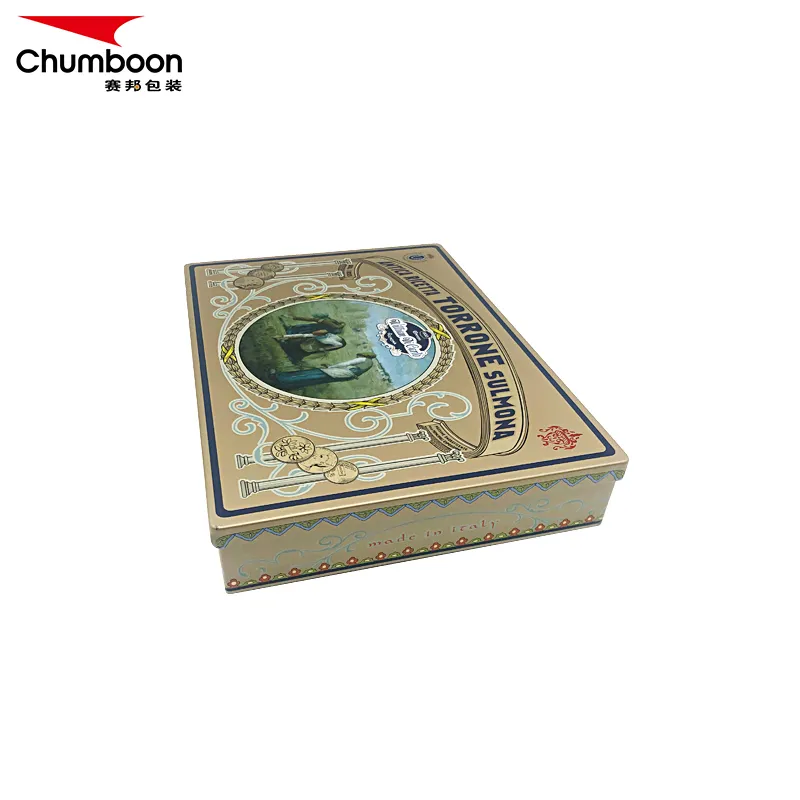

1. High-end candy tin box

High-end candy tin box usually uses tin-plated thin steel plate or aluminum as the main material to ensure the high quality and high aesthetics of the product. For example, the chocolate candy tin box of the well-known brand Ferrero uses tin-plated thin steel plate, and the surface is exquisitely printed and coated, which improves the grade and market competitiveness of the product.

2. Economical candy tin box

Economical candy tin box uses more plastic materials such as polyethylene or polypropylene to reduce production costs and meet the needs of large-scale production and sales. For example, the common hard candy and soft candy packaging cans on the market are mostly made of polyethylene, which not only ensures protection performance but also controls costs.

3. Environmentally friendly candy tin box

With the increase in environmental awareness, some brands have begun to use paper materials or composite materials to produce environmentally friendly candy tin boxes. For example, a certain brand of environmentally friendly candy tin box uses kraft paper and aluminum foil composite materials, which not only ensures protection performance but also meets environmental protection requirements, and is popular with consumers.

Summary and Outlook

Through the analysis of various materials, it can be seen that there is no single answer to the best material for making candy tin box, but it needs to be selected according to specific needs.

Metal materials such as tin-plated steel sheets and aluminum are suitable for high-end candy tin boxes, with good protection and aesthetics; plastic materials such as polyethylene and polypropylene are suitable for economical candy tin boxes, with the advantages of low cost and good processability; paper materials and composite materials are suitable for environmentally friendly candy tin boxes, in line with the needs of sustainable development.