Tin cans are a packaging material widely used in food, beverage, chemical and pharmaceutical industries. It is made of tinplate as the main material and formed through tin plating process. It has excellent anti-corrosion performance and sealing performance.

However, tin cans also present some drawbacks and challenges. This article will start from the advantages and disadvantages of tin cans, and analyze their applications and future development trends in various fields in detail.

What are the advantages of tin cans?

1. Excellent anti-corrosion performance

One of the most significant advantages of tin cans is their excellent anti-corrosion properties. The tin plating layer can effectively prevent the iron sheet from coming into contact with oxygen and moisture in the air to avoid rust and corrosion. This property makes tin cans particularly suitable for long-term storage of food and beverages, ensuring the safety and quality of the contents.

2. Excellent sealing performance

Tin cans have good sealing properties, which can effectively prevent outside air, moisture and pollutants from entering the can, maintaining the original flavor and quality of the contents. This characteristic makes tin cans widely used in the packaging of food, beverages and chemical products.

3. Sturdy and durable

Tin cans are made of tinplate material, which has high strength and hardness, can withstand a certain amount of external impact and extrusion, and is not easily deformed or damaged. Its rugged and durable nature gives it good protection during transportation and storage.

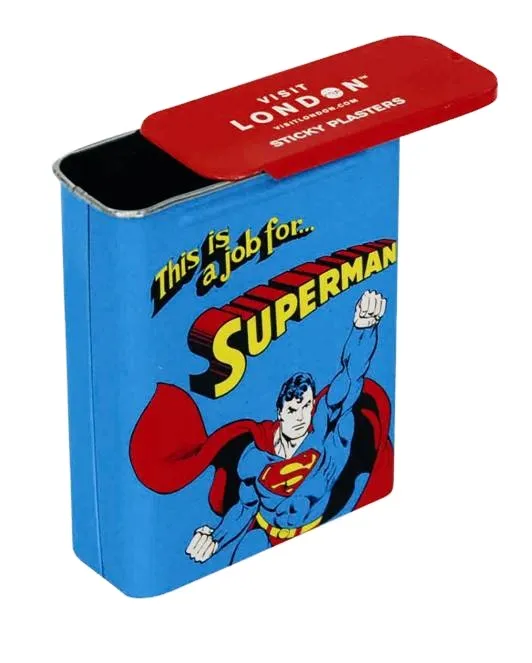

4. Excellent printing effect

The surface of the tin can is smooth and flat, which is suitable for various printing processes. It can achieve high-quality pattern and text printing and enhance the visual effect and brand image of the product. This has important implications for marketing and consumer appeal.

5. Environmentally friendly and recyclable

Tin can materials have a high recyclability value. Both tinplate and tin plating can be recycled and reused, effectively reducing resource waste and environmental pollution. The environmental protection performance of tin cans meets the requirements of modern society for sustainable development.

What are the disadvantages of tin cans?

1. Higher cost

Tin cans are relatively expensive to produce. First of all, the price of tinplate materials is relatively high. Secondly, the tin plating process requires certain technical and equipment support, which increases production costs. This may affect the competitiveness of tin cans in certain applications.

2. Heavy weight

Compared with lightweight packaging materials such as aluminum cans, tin cans are heavier. This may cause inconvenience during transportation and carrying, increase transportation costs and energy consumption. For products that require lightweight packaging, tin cans may not be the best choice.

3. Vulnerable to damage by external forces

Although tin cans have a certain degree of strength and hardness, they may still be deformed or damaged when impacted by large external forces. Especially in high-intensity transportation and storage environments, the impact resistance of tin cans may be insufficient, affecting the safety of the contents.

4. Susceptible to chemical corrosion

Although the tin plating layer has anti-corrosion properties, in some strong acid or alkali environments, tin cans may still be subject to chemical corrosion, resulting in damage to the plating layer and contamination of the contents. Therefore, when using tin cans to package chemical products, special attention needs to be paid to their scope of application and conditions of use.

5. Complex production process

The production process of tin cans is relatively complex, including material preparation, tin plating, forming, sealing and other links. This requires higher technical and equipment support, increasing production difficulty and cost.

What are the application fields of tin cans?

1. Food industry

Tin cans are widely used in the food industry for packaging of canned foods, condiments, beverages and other products. Its excellent antiseptic properties and sealing properties can effectively extend the shelf life of food and ensure food safety and quality. At the same time, the high-quality printing effect on the surface of the tin can can enhance the market competitiveness and brand image of the product.

2. Chemical industry

Tin cans are used in the chemical industry to package chemical products such as paints, coatings, and solvents. Its anti-corrosion and sealing properties can prevent chemical leakage and contamination, ensuring safe storage and transportation of products. However, for certain strongly acidic or alkaline chemicals, special attention needs to be paid to the suitability of tin cans.

3. Pharmaceutical industry

Tin cans are used in the pharmaceutical industry to package medicines, health care products and other products. Its sealing performance can prevent drugs from getting damp and oxidized, ensuring the effectiveness and stability of drugs. At the same time, the sturdy and durable nature of tin cans prevents pharmaceuticals from being damaged during transportation and storage.

4. Electronics industry

Tin cans are used in the electronics industry to package electronic components, semiconductors and other products. Its anti-corrosion and sealing properties can prevent electronic products from moisture and oxidation, ensuring product quality and performance. At the same time, the sturdy and durable nature of tin cans can prevent electronic products from being damaged during transportation and storage.

Conclusion

Tin cans have excellent anti-corrosion properties, sealing properties and durability, and are widely used in food, chemical, pharmaceutical and electronic industries. However, tin cans also have disadvantages such as higher cost, weight, and susceptibility to chemical corrosion.

Through technological innovation and process improvement, the performance and competitiveness of tin cans can be continuously improved to meet the needs of the market and environmental protection. In the future, tin cans will develop in the direction of lightweight, environmental protection and multi-functionality, providing better packaging solutions for various industries.