As a packaging material widely used in food, beverage and chemical industries, the problem of waste generated in the production process of electrolytic tinplate sheet has always attracted much attention. Reducing production waste not only helps to reduce production costs, but also reduces environmental pollution and enhances the sustainable development capabilities of enterprises.

This article will explore how to effectively reduce waste in the production process of electrolytic tinplate sheet from multiple aspects such as raw material selection, production process optimization, equipment improvement and waste recycling.

Overview of electrolytic tinplate sheet

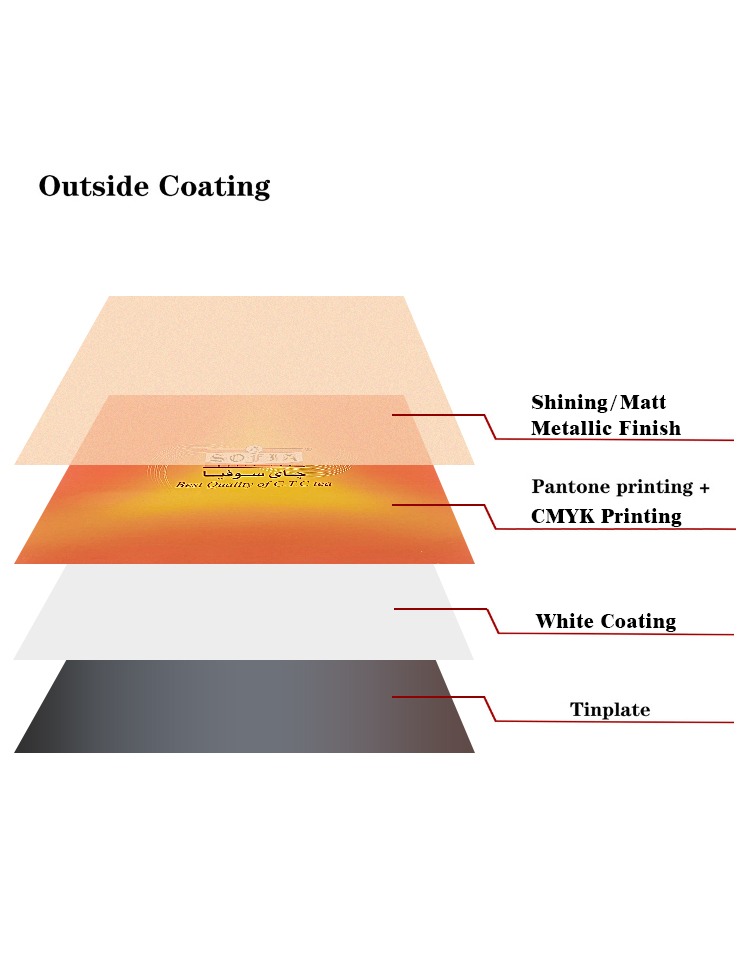

Electrolytic tinplate sheet is a metal material made by electroplating a layer of tin on a low-carbon steel substrate, with excellent anti-corrosion properties and mechanical strength. A certain amount of waste will be generated in its production process, including scraps, waste tin slag, wastewater and waste gas. How to reduce these wastes is not only an important way for enterprises to reduce production costs, but also an inevitable requirement for fulfilling environmental protection responsibilities and achieving sustainable development.

How to reduce production waste in the process of electrolytic tinplate sheet?

1. Optimize raw material selection:

Choosing high-quality, appropriately sized low-carbon steel coils as the base material can reduce the generation of waste due to raw material defects. At the same time, reasonable raw material procurement planning and inventory management can also help reduce waste. For example, by establishing a long-term cooperative relationship with suppliers to ensure stable supply, waste caused by shortage or surplus of raw materials can be reduced.

2. Improve production process:

● Refined management: Reduce waste in the process through refined production management and process control. For example, optimize the parameters of processes such as pickling, cold rolling and electroplating to ensure the stability and efficiency of the production process and reduce the scrap rate.

● Automated production: The introduction of automated production lines and intelligent control systems can improve production efficiency and reduce waste caused by human operating errors. At the same time, automated equipment can monitor the production status in real time, detect and solve problems in a timely manner, and further reduce waste generation.

3. Equipment improvement and maintenance:

● Efficient equipment: The use of efficient and energy-saving production equipment, such as advanced pickling equipment, cold rolling mills and electroplating equipment, can not only improve production efficiency, but also reduce waste generation. For example, efficient pickling equipment can remove the oxide layer more evenly and reduce the generation of pickling waste liquid.

● Regular maintenance: Regularly maintain the production equipment to ensure its normal operation and reduce production interruptions and waste generation caused by equipment failure. At the same time, replace worn parts in time to keep the equipment in the best working condition.

4. Waste reuse:

● Scraps recycling: Scraps generated during the production process can be recycled and reused and put back into production. For example, scraps can be returned to the furnace and re-smelted to make new steel coils, reducing the consumption of raw materials.

● Waste tin slag treatment: The waste tin slag generated during the electroplating process can be recycled and processed to extract valuable components such as tin and iron, and reused in production. The use of advanced recycling technology can improve the recovery rate of waste tin slag and reduce waste emissions.

● Wastewater treatment and recycling: The wastewater generated during the production of electrolytic tinplate sheet can be purified by advanced wastewater treatment technology, and recycled in the production process after meeting the emission standards, reducing the consumption of water resources and the discharge of wastewater.

5. Application of environmentally friendly processes:

● Green electroplating technology: The use of environmentally friendly electroplating technology and electroplating solution, such as cyanide-free electroplating process and low-toxic electroplating solution, can reduce the generation of harmful substances and reduce the difficulty and cost of treating wastewater and waste gas.

● Energy-saving and emission-reduction technology: The introduction of energy-saving and emission-reduction technology, such as energy recovery devices and low-energy consumption equipment, can reduce energy consumption and waste gas emissions, and reduce the environmental impact of the production process.

Successful case analysis

A well-known electrolytic tinplate sheet manufacturer has achieved remarkable results through a series of measures to reduce waste. The company first optimized the raw material procurement process to ensure that the quality and specifications of the raw materials meet the production requirements and reduce the generation of waste due to unqualified materials. Secondly, the company introduced automated production lines and intelligent control systems to improve production efficiency and reduce human operating errors and scrap rates. At the same time, by regularly maintaining and upgrading production equipment to ensure the stable operation of the equipment, waste generation is further reduced.

In terms of waste recycling, the company has established a complete waste recycling system to recycle the scraps and waste tin slag generated during the production process and reuse them in production, reducing the consumption of raw materials and the discharge of waste. In addition, the company has also adopted advanced wastewater treatment and recycling technologies to effectively reduce the discharge of wastewater and reduce the consumption of water resources.

Conclusion

Reducing waste in the production process of electrolytic tinplate sheet is not only an effective way for enterprises to reduce production costs and enhance competitiveness, but also an important measure to fulfill environmental protection responsibilities and achieve sustainable development.

In the future, with the continuous advancement of technology and the improvement of environmental protection requirements, electrolytic tinplate sheet manufacturers need to continue to innovate, continuously optimize production processes and management models, further reduce the generation of waste, and contribute to the realization of green manufacturing and sustainable development.